In the world of electronics and contemporary technology, the relevance of printed motherboard (PCBs) can not be overstated. These intricate elements form the foundation of essentially every electronic device, from computer systems and smartphones to family appliances and medical tools. A PCB, frequently described as a circuit card, gives the vital framework for connecting different electronic components through conductive tracks engraved onto non-conductive substratums. Among the lots of kinds of PCBs, the rigid-flex circuit boards stand apart as an impressive innovation. These are hybrid boards that incorporate the most effective characteristics of flexible and rigid PCBs, permitting vibrant layouts that can bend and twist without giving up structural integrity. This adaptability makes rigid-flex circuits particularly attractive for applications where area is limited, such as in mobile gadgets and wearables.

The production of PCBs, specifically in high-density interconnect (HDI) arrangements, has progressed as the need for smaller sized, faster, and a lot more reliable electronics rises. HDI PCBs integrate finer lines and rooms, as well as smaller sized vias, which allow for greater component density.

Joint endeavors with printed circuit manufacturers are essential in ensuring that PCB layouts shift smoothly from conceptual phases to actual items. Printed circuit board assembly (PCBA) ends up being an important step in the process where various parts are soldered onto the PCB in exact arrangements to ensure optimum procedure.

Quick turnaround PCB prototyping services have gotten popularity as businesses make every effort to bring their items to market quickly. This agile manufacturing strategy enables companies to test and verify their styles prior to dedicating to full production runs. Such prototyping is essential in minimizing time-to-market and enables repetitive improvements based upon initial screening results. Suppliers offer flexible choices for both low-volume and high-volume orders to fit varied manufacturing demands. With the enhancing accessibility of fast-turn PCB services, the barriers to prototype advancement have actually been significantly reduced, allowing an environment of technology.

Flexible printed motherboard (FPCBs) are another amazing classification that has actually amassed attention due to their distinct abilities. These boards are made to be lightweight and ultra-thin, providing the capability to bend, fold, or spin without compromising performance. This flexibility makes them a perfect choice for applications in various areas, consisting of consumer electronics, automobile, and medical tools. FPCBs can additionally help streamline assembly processes, as their design enables an extra portable type aspect, which typically leads to fewer connection factors and possible failing settings.

Thermal management, for instance, plays a vital duty in PCB design, especially in electronic products that run under high tons. Designers have to take into consideration materials with good thermal conductivity, such as heavy copper PCBs, which help dissipate heat efficiently.

The understanding of printed circuit card design is essential for engineers and product designers. Understanding numerous elements such as circuit card assembly, which consists of the process of soldering parts onto a PCB, can dramatically influence completion item's high quality. Effective design practices ensure that electrical paths are maximized and that the general design reduces interference, thus enhancing life-spans and efficiency. In addition, utilizing tools and software made for PCB design and simulation can considerably improve the design process, allowing makers to swiftly alter prototypes based upon testing end results.

Variations in PCB kinds such as 2-layer, 4-layer, and multi-layer boards are each matched to specific applications based upon their complexity and the variety of components that need to be incorporated. Four-layer PCBs give enhanced transmitting capabilities, essential for a lot more innovative electronics. more info These boards help in handling signal honesty and offer enough space to path traces extra successfully, guaranteeing even more reliable performance in every little thing from smartphones to complex commercial tools.

Contract PCB assembly services have actually become an important source for companies doing not have the internal capabilities to deal with complicated assembly procedures. These services commonly consist of comprehensive assistance ranging from design examination to full-blown production, supplying services with the versatility they need to meet varying demands. By partnering with established manufacturers, businesses can utilize expertise in areas such as HDI read more layouts, microvias, and multilayer PCBs, thereby increasing their item offerings without investing heavily in devices and labor.

Selecting the ideal materials for PCB production is important, and considerations often consist of the ecological requirements applicable to their usage, consisting of UL ratings, such as 94V-0, which concerns terminate retardancy. Manufacturers require to stay educated regarding click here compliance regulations to make sure that their products fulfill security standards while additionally performing optimally in their desired application settings.

The assimilation of superhigh frequency (RF) innovation into PCBs is an additional area seeing raised relevance, specifically with the rise of cordless communication gadgets. RF PCBs must be carefully created, with considerations for resistance control and reduced signal loss due to the high regularities involved. This expertise requires understanding of RF circuit design and might involve in-depth electro-magnetic simulations as engineers function to attain optimal performance in portable types.

As modern technology continues to develop, manufacturers are progressively embracing automation and advanced fabrication procedures to improve performance. Technologies such as automated optical inspection (AOI) and surface mount technology (SMT) are now conventional methods, permitting high-speed assembly and regular top quality control. Technologies in PCB manufacturing additionally reach brand-new materials and techniques, such as making use of embedded technology where components are ingrained directly within the layers of the PCB, even more saving space and improving performance.

In conclusion, the printed circuit board industry consistently adjusts to transforming needs and technological developments, reflecting the dynamic landscape of electronics. Whether through PCBA, flexible circuits, or fast-turn prototypes, the products, styles, and processes connected with PCBs are crucial fit the future of electronic tools. Manufacturers who remain at the leading edge of these developments not only boost their competitive edge but additionally allow the growth and growth of advanced technologies that specify modern life. With the ever-increasing intricacy of circuits and the demand for reliable, high-performance services, the PCB sector stays a keystone of technical progress, driving the means we communicate with devices and eventually connecting our physical and digital worlds.

Danny Tamberelli Then & Now!

Danny Tamberelli Then & Now! Devin Ratray Then & Now!

Devin Ratray Then & Now! Michael Bower Then & Now!

Michael Bower Then & Now! Katie Holmes Then & Now!

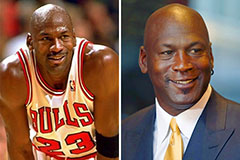

Katie Holmes Then & Now! Michael Jordan Then & Now!

Michael Jordan Then & Now!